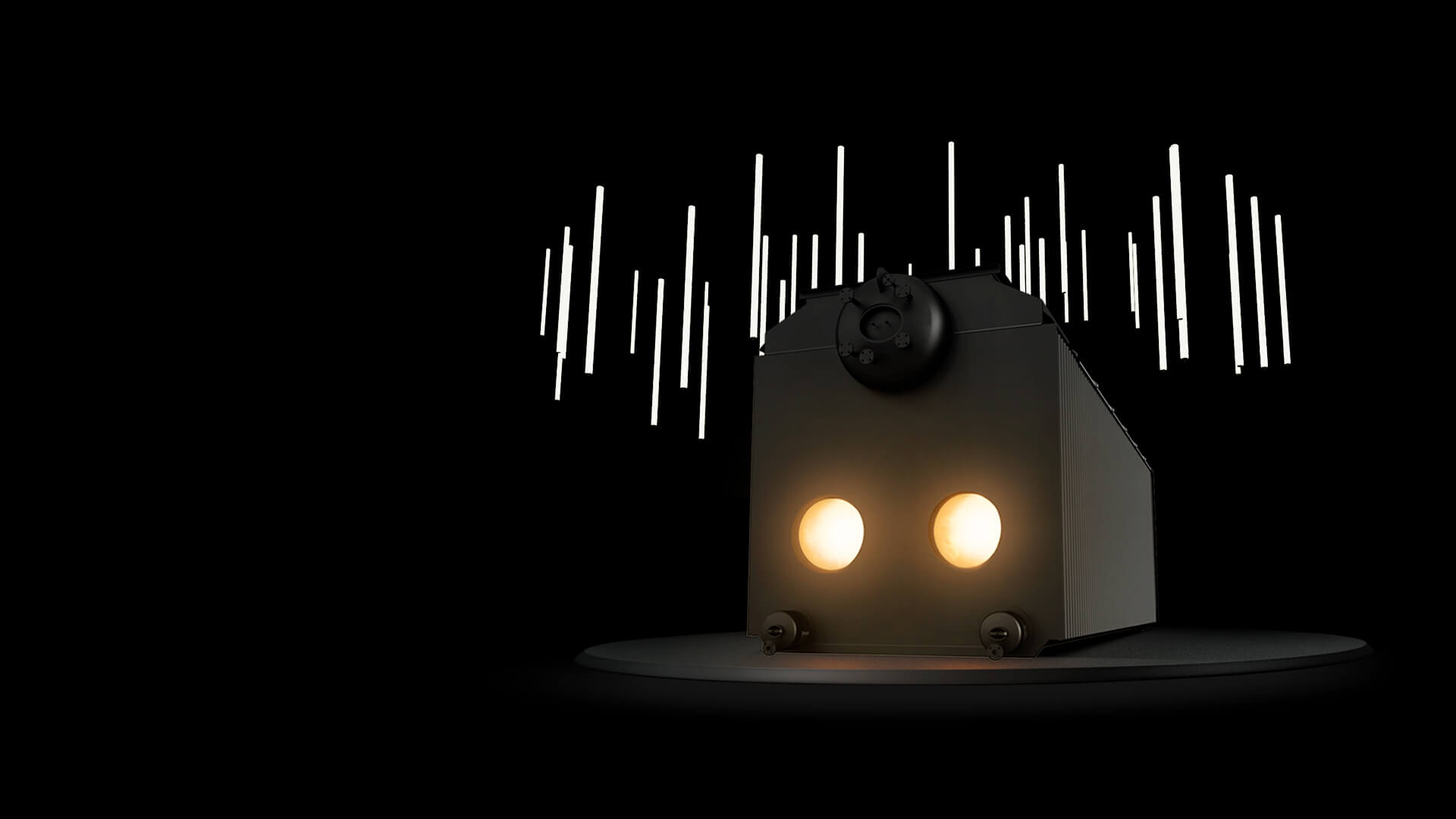

NOMAD

It’s true what they say, good things do come in small packages. In the case of the NOMADTM steam boiler, the brainchild of Simoneau’s seasoned engineers, this idiom rings particularly true. This novel, compact A-type package boiler is designed to produce optimal energy levels, namely in line with the needs of today’s urban infrastructures and campuses. Its configuration, especially in terms of height, is neatly thought-out to allow for quick and easy transportation, allowing you in turn to save on costs and avoid a slew of logistical issues. You don’t even need a special permit to transport it!

“In a nutshell, the NOMADTM boiler proves that high-performance and mobility CAN go hand in hand.”

York University + NOMADTM: A match made in energy heaven

Much like the boiler makers at Simoneau, York University is driven by R&D and innovation to help shape a better tomorrow for our future generations. At the time, the university was looking for a cost-effective boiler solution with all the benefits of a district heater. It also had to be a low-profile/light weight unit with great capacity that could easily go anywhere without damaging local infrastructures. The innovative minds at Simoneau stepped in and struck a partnership with York University, which eventually led to the installation of the NOMADTM steam boiler on the campus grounds.

Going forward, the unconventional A-type boiler was able to provide York University with:

- 100,000 pounds of steam per hour

- Ramp up time that averaged 25 minutes

- Combustion efficiency at 85.19%

Not bad for a compact boiler that can easily glide under overpasses, eh?

So, what’s going on inside that boiler, anyway?

The secret to the NOMADTM steam boiler is its innovative A-type configuration. It’s the result of Simoneau’s extensive engineering expertise coupled with the benefits provided by their patented, flexible watertube boilers.

By adding a separated fin tube economizer to the flexible tube configuration (made up of a series of narrow, flexible tubes that are thermal-shock resistant), combustion efficiency can reach an average of 85%. The boiler’s sturdy frame is created by large downcomers placed at each corner. PLUS, to ensure its low-profile, Simoneau uses a rectangular combustion chamber that’s equipped with two burners that actually operate as one.

Good news for the environment: the NOMADTM design also meets NOx emission standards due in large part to the fact that it uses very little refractory when firing natural gas.

“Quicker start-up, efficient, robust, compact design, easy-to-haul; What’s not to love about the NOMADTM?”