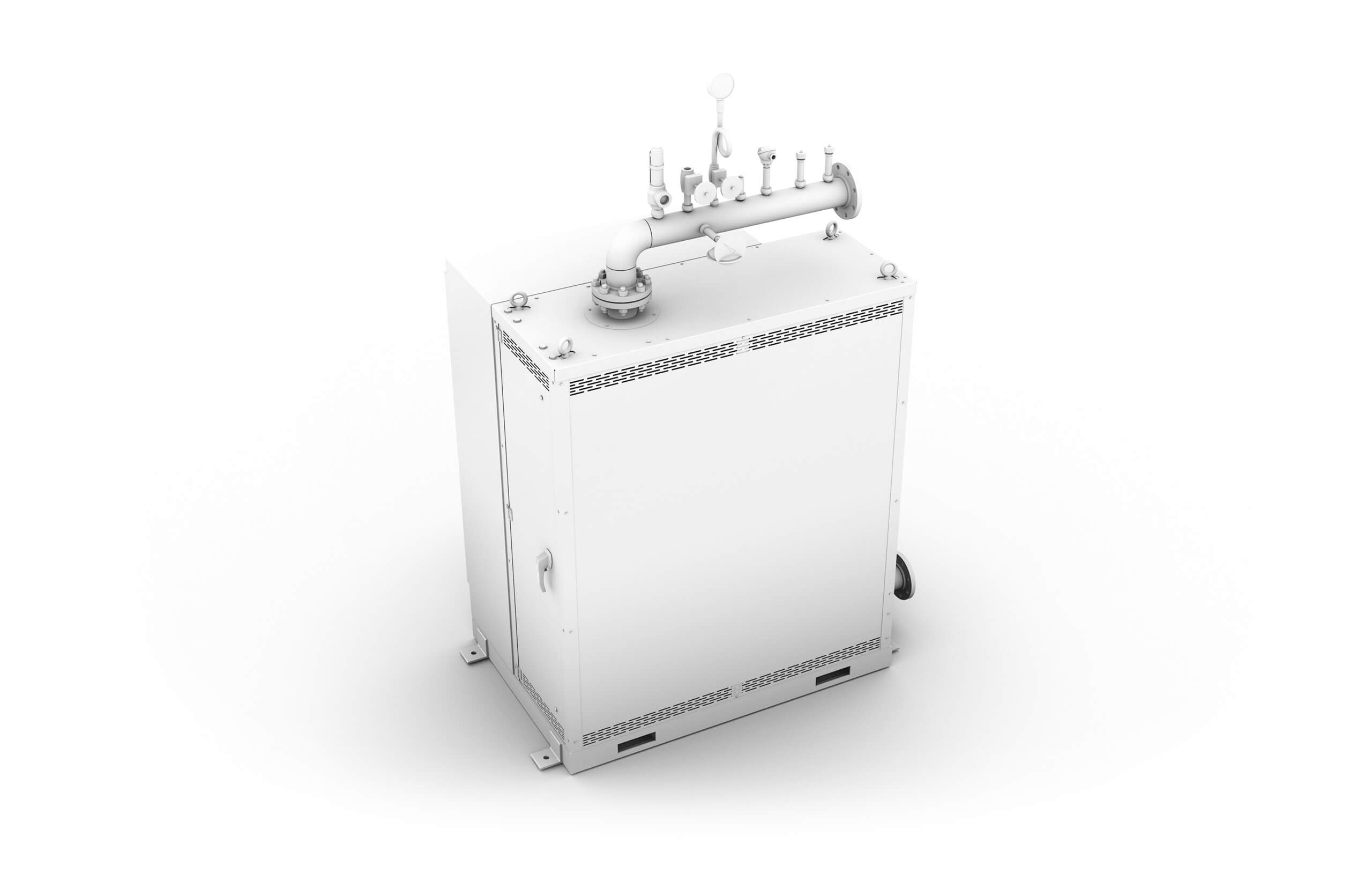

E-VOLTA ELECTRIC STEAM BOILERS (HIGH PRESSURE OR LOW PRESSURE)

Engineered to deftly handle today’s industrial steam and heating needs for various sectors, the eVolta® is Simoneau’s innovative electric steam boiler designed to help you reach your decarbonization goals.

The eVolta®, the electric boiler of the future, incorporates all the features needed to generate high-grade steam quality while eliminating the risk of carryover. The flanges are positioned in the boiler as such to ensure optimal steam generation.

By leveraging Canada’s great capacity in industrial electric systems, electrification solutions and hydroelectric engineering, our experienced, multidisciplinary team offers you an electric boiler solution that incorporates the latest innovations and complies with the industry’s strictest manufacturing standards.

Whether you’re looking for a reliable energy supply source for an entire industrial sector or to access industrial-grade heat, you’re tapping into maximized energy efficiency with the eVolta® and actively reducing your carbon footprint thanks in part to its dual energy capacity – allowing you for example to use your building’s energy source for the ramping-up process or for overnight standby maintenance.